Add to Cart

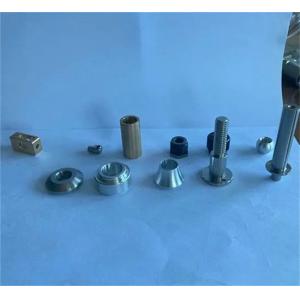

Metal CNC Machining is a high precision manufacturing process that utilizes a CNC Lathe to produce custom metal parts. It is the most advanced technology for producing metal components with unparalleled precision and efficiency.

The equipment used in Metal CNC Machining is a CNC Lathe, which is a computer controlled machine tool that can perform a wide range of operations such as drilling, turning, milling, and threading. This allows for the production of complex and intricate metal parts with consistent quality and accuracy.

The material used in Metal CNC Machining includes a variety of metals such as Titanium, Aluminum, Stainless Steel, Steel, and Brass. These materials are known for their strength, durability, and resistance to corrosion, making them ideal for machinery parts that require high performance and reliability.

The process of Metal CNC Machining involves the use of computerized numerical control (CNC) technology to control the movements of the CNC Lathe. This ensures precise and repeatable movements, resulting in high quality and consistent metal parts.

Metal CNC Machining offers customized solutions for a wide range of industries, from automotive and aerospace to medical and electronics. The size of the metal parts can be customized according to the specific requirements of the customer, making it a versatile manufacturing process.

With Metal CNC Machining, customers can expect high precision and accuracy in the production of their metal parts. The advanced technology and skilled technicians ensure that each part is produced to the exact specifications, resulting in a perfect fit and function.

In addition to its precision, Metal CNC Machining also offers durability. The use of high quality materials and precise machining process ensures that the metal parts can withstand heavy loads and harsh environments, making them long-lasting and reliable.

Moreover, Metal CNC Machining is an efficient process that saves time and cost. With the use of CNC technology, the production process is streamlined, reducing the need for manual labor and minimizing errors. This results in faster production times and cost savings for customers.

In conclusion, Metal CNC Machining is a cutting-edge technology that offers high precision, customization, durability, and efficiency in the production of metal parts. With its wide range of applications and superior performance, it is the ideal choice for machinery parts that require the highest quality and reliability.

| Metal CNC Machining | |

|---|---|

| Process: | CNC Machining |

| Shipping: | By Air/Sea/Express |

| Surface Finish: | Polishing, Smooth |

| Tolerance: | ±0.01mm |

| Application: | Machinery Parts |

| Lead Time: | 7-15 Days |

| MOQ: | 1 Piece |

| Material: | Titanium, Aluminum, Stainless Steel & Steel, Brass |

| Equipment: | CNC Lathe |

| Service: | OEM/ODM |

Brand Name: Superior Prototype

Model Number: SPH90

Place of Origin: China, GUA

Certification: ISO27001;2021,ISO 9001:2015

Minimum Order Quantity: 1

Price: USD

Packaging Details: Paper carton or Wood carton with full protection foam inside

Delivery Time: 3-8 work days

Payment Terms: T/T, Paypal

Supply Ability: 10000

MOQ: 1 Piece

Process: CNC Machining

Shipping: By Air/Sea/Express

Application: Machinery Parts

Equipment: CNC Lathe

Introducing Superior Prototype's SPH90 Metal CNC Machining product - the perfect solution for all your precision metal part needs. Our state-of-the-art Metal Computer Numerically Controlled Machining process ensures high quality and accurate results every time.

With ISO27001 and ISO 9001:2015 certification, you can trust in our commitment to quality and excellence. Our manufacturing facility is located in China, GUA and we have a minimum order quantity of just 1 piece, making our services accessible to businesses of all sizes.

Our packaging options include paper or wood cartons with full protection foam inside, ensuring the safe delivery of your metal parts. We also offer a variety of shipping options, including air, sea, and express, to meet your specific needs and deadlines.

Our CNC Lathe equipment allows us to produce a wide range of metal parts with precision and efficiency. From small, intricate parts to larger components, we have the capabilities to meet your requirements.

Our Metal CNC Machining is suitable for various applications, particularly in the machinery industry. With a supply ability of 10000 and a quick turnaround time of 3-8 work days, we can meet your production demands and ensure timely delivery.

Choose Superior Prototype for your metal part needs and experience superior quality, precision, and efficiency. Contact us today to discuss your project and request a quote.

Our Metal CNC Machining products are carefully packaged to ensure safe delivery to our customers. We understand the importance of protecting your products during transportation, and we take every precaution to ensure that they arrive in pristine condition.

All Metal CNC Machining products are first wrapped in protective materials to prevent any damage during shipping. We then place them in durable, corrugated cardboard boxes that are designed to withstand the rigors of transportation. For larger orders, we use wooden crates or pallets to ensure the safety of the products.

We also offer customized packaging options for our customers, such as labeling and branding, to meet their specific requirements.

We work with reliable shipping partners to ensure that your Metal CNC Machining products are delivered on time and in the best condition. We offer various shipping options, including air freight, sea freight, and ground transportation, depending on the destination and urgency of the order.

Our team carefully tracks and monitors all shipments to provide real-time updates to our customers. We also provide insurance coverage for all shipments to protect against any unforeseen events during transportation.

At Metal CNC Machining, we strive to provide the best packaging and shipping services to ensure that your products are delivered safely and efficiently.